"whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU" (whiskey-business)

"whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU" (whiskey-business)

02/04/2016 at 20:45 ē Filed to: None

1

1

18

18

"whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU" (whiskey-business)

"whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU" (whiskey-business)

02/04/2016 at 20:45 ē Filed to: None |  1 1

|  18 18 |

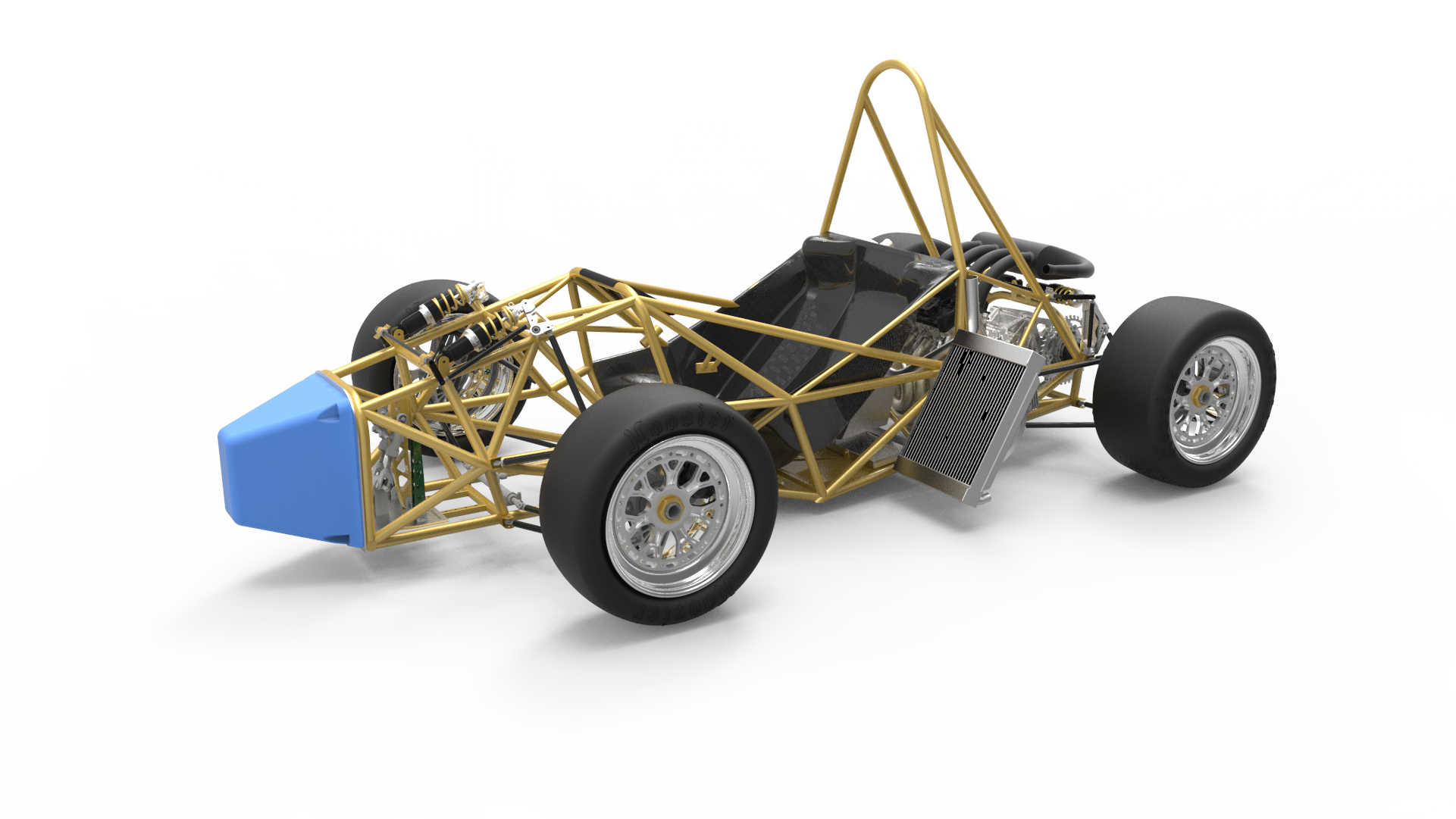

My schoolís Formula Team, of which I am finally a fully integrated, productive member of, is in full manufacturing season. This means lots of awesome pictures to be taken.

My part of the team at this point is on the business team where Iím needed most, primarily in the creation and promotion of our teams website and looking for sponsors for kinematics software. However, Iím putting in the legwork to help design the suspension next year, and all the webmaster work is fast-tracking me (pun intended) me into the drivers seat of our new car.

I thought you all might enjoy a little photodump of stuff from around our shop

Bman76 (no it doesn't need a WS6 hood) is dead, long live Bman76 M. Arch

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

Bman76 (no it doesn't need a WS6 hood) is dead, long live Bman76 M. Arch

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

02/04/2016 at 21:02 |

|

Two people TIG welding together? Thatís different.

DrJohannVegas

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

DrJohannVegas

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

02/04/2016 at 21:18 |

|

(Nostalgia intensifies.)

Alexander LaRocca

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

Alexander LaRocca

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

02/04/2016 at 21:21 |

|

What a coincidence! I just joined up with Oakland Universityís FSAE and am developing a business team there. I guess Iíll be seeing you around.

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> Alexander LaRocca

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> Alexander LaRocca

02/04/2016 at 21:23 |

|

Thatís awesome! What year are you? Iím sure Iíll see you at MIS and maybe Lincoln this year.

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> Bman76 (no it doesn't need a WS6 hood) is dead, long live Bman76 M. Arch

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> Bman76 (no it doesn't need a WS6 hood) is dead, long live Bman76 M. Arch

02/04/2016 at 21:23 |

|

It was interesting to see. I believe one guy was practicing beads and the other was practicing feeding fill rod.

Alexander LaRocca

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

Alexander LaRocca

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

02/04/2016 at 21:29 |

|

Iím a junior, marketing major. My first job is to get new material sponsors. You?

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> Alexander LaRocca

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> Alexander LaRocca

02/04/2016 at 21:30 |

|

Sophomore, Mechanical Engineering. Iím working on mathematical tire models using MATLAB and finding cheaper software for suspension design. Although for the moment Iím doing all the website work, since our whole business team quit.

thedevilinside

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

thedevilinside

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

02/04/2016 at 21:45 |

|

Are you doing Pacejka equation stuff?

Bman76 (no it doesn't need a WS6 hood) is dead, long live Bman76 M. Arch

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

Bman76 (no it doesn't need a WS6 hood) is dead, long live Bman76 M. Arch

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

02/04/2016 at 21:46 |

|

Iím terrible (but improving) at TIG, itís a lot of coordination of movements to get right. Especially when youíre welding beyond the machineís capacity and everything involved is super-heated.

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> thedevilinside

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> thedevilinside

02/04/2016 at 22:05 |

|

Yes sir, Im currently working on a few different software packages. One to use the curve fitting toolbox to fit curves to Tire Test Consortium data for comparison between tire combinations, and a GUI-based program to assist in finding what values of the Magic Formula coefficients most closely match the curve from the first program.

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> Bman76 (no it doesn't need a WS6 hood) is dead, long live Bman76 M. Arch

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> Bman76 (no it doesn't need a WS6 hood) is dead, long live Bman76 M. Arch

02/04/2016 at 22:06 |

|

That sounds like a dangerous situation to put yourself in. . . You never want to go outside the operating range of the machine.

Bman76 (no it doesn't need a WS6 hood) M. Arch

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

Bman76 (no it doesn't need a WS6 hood) M. Arch

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

02/04/2016 at 23:13 |

|

We were welding 3/8" plate on a machine rated for 1/4". We couldnít touch the work piece for over an hour afterwords.

uofime-2

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

uofime-2

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

02/05/2016 at 10:53 |

|

Are you using Optimum G software (specifically optimum k and optimum tire)?

They give good discounts to student programs.

Also gloves, long sleeves and baggy clothing are a no no when using milling machines

Mustafaluigi

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

Mustafaluigi

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

02/05/2016 at 11:16 |

|

A guy on my team was heavily involved with tire modeling and data. Heís now getting his masters in motorsports engineering at Oxfords Brooks in the UK.

2BWise

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

2BWise

> whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

02/05/2016 at 14:53 |

|

Good luck. Lots of fond memories of FSAE. Great way to learn anything and everything you could ever imagine about cars.

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> Bman76 (no it doesn't need a WS6 hood) M. Arch

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> Bman76 (no it doesn't need a WS6 hood) M. Arch

02/05/2016 at 17:21 |

|

Oh man, I donít envy you there.

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> uofime-2

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> uofime-2

02/05/2016 at 17:24 |

|

Yes, and even with the discounts, its still a fair amount. And I know there are like 14 things wrong with that machining picture. That isnít me and I do not recommend that kind of thing.

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> Mustafaluigi

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> Mustafaluigi

02/05/2016 at 18:43 |

|

Thatís what I hope to do some day, although getting a job will likely come before the masters.